Celebrating 40 years of aerospace service and experience, integrating the knowledge and success of our team from our Issoudun, France facility across the global Mannesmann facilities to bring our aerospace & defence customers a truly versatile product offering.

Innovating to set tomorrow’s standards for lighter, stronger materials – operating under higher pressures to meet and exceed exacting performance expectations.

Bringing together our manufacturing facilities in Germany, France, Italy and USA whilst embracing and developing our manufacturing relationship in India.

Recognizing the needs of our customers for quality, cost competitiveness and service.

Service & Flexibility

Rapid deliveries, supporting breakdown requirements from our EU and US production facilities.

Utilising the flexibility of its Issoudun, France and Houston, USA production facilities MST has launched a new service offering a manufacturing lead time of 6 weeks, to support rapid delivery needs on breakdown requirements.

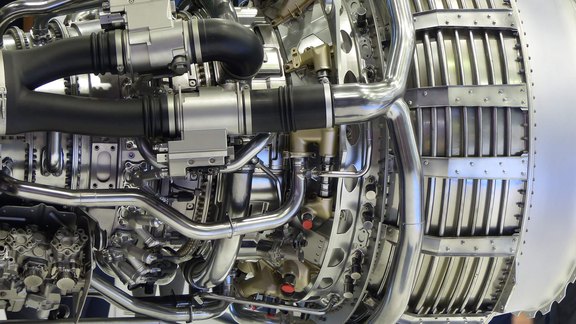

Engine fuel systems, air bleed, heat exchangers and hydraulic controls

Austenitic, martensitic PH grades and nickel superalloys (Ni-Cr, Ni-Co) for high temperature creep and oxidation resistance.

Supplied as straight tubes, components or profiles.

| PRODUCT: ENGINE TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 1.6 | 0.063 |

| max | 38.1 | 1.5 |

| WT range | mm | Inch |

| min | 0.1 | 0.004 |

| max | 11.0 | 04.33 |

Cold finished production size range.

Airframe Hydraulics & flow measurement system tubes & components

From hydraulic control systems operating at 3000/5000 psi to flow measurement pitot tubes operating at temperature extremes our high strength-to-weight austenitic, age-hardenable martensitic alloys and nickel alloys.

| PRODUCT: AIRFRAME TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 1.6 | 0.063 |

| max | 51.0 | 0.567 |

| WT range | mm | Inch |

| min | 0.1 | 0.004 |

| max | 14.4 | 0.567 |

Structural, mechanical tube & components for landing gear, brakes and actuation systems

From mechanical hollow bar for machining into critical structural parts to precision tubes in round, profile or component form. Austenitic stainless, martensitic stainless PH grades and nickel alloys.

| PRODUCT: STRUCTURAL AND ACTUATION TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 6.0 | 0.25 |

| max | 280 | 11.0 |

| WT range | mm | Inch |

| min | 0.2 | 0.008 |

| max Cold Finished | 14.4 | 0.567 |

| max Hot Finished | 60.0 | 2.36 |

Cold finished production size range.

Aerospace Grades

| Grades | MST designation | Typical specification | Nearest equivalent standard | Typical chemical composition | Density | Min. mechanical prop. at RT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | Cmax | Cr | Ni | Mo | Cu | others | Rp0.2 Yield Strength | Rm Tensile Strength | |||||||

| g/cm3 | lb/in3 | MPa | ksi | MPa | ksi | |||||||||||

| Stainless Austenitic | ||||||||||||||||

| 304L | DMV 304L | AMS5564 | S30403 | 1.4306 | 0.03 | 19.0 | 11.0 | 7.9 | 0.29 | 170 | 5 | 485 | 70 | |||

| 321 | DMV 321 | AMS5557 | S32100 | 1.4541 | 0.03 | 18.5 | 10.5 | 5 x C < Ti < 0.6 | 7.9 | 0.29 | 170 | 25 | 485 | 70 | ||

| 347 | DMV 347 | AMS5557 | S34700 | 1.4550 | 0.08 | 18.5 | 11.0 | 10 x C < Nb < 1.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | ||

| 316L | DMV 316L | AMS5573 | S31603 | 1.4404 | 0.03 | 17.0 | 12.0 | 2.25 | 8.0 | 0.29 | 170 | 25 | 485 | 70 | ||

| 21-6-9 | DMV 2169 | AMS 5561 | S21900 | 0.08 | 19.0 | 5.5 | Mn 8.0 | 7.9 | 0.29 | 330 | 48 | 655 | 95 | |||

| Martensitic | ||||||||||||||||

| 17 4 PH | DMV 174 | AMS 5643 | S17400 | 1.4542 | 0.07 | 17.0 | 4.0 | 4.0 | 7.9 | 0.29 | 1140 | 165 | 1170 | 170 | ||

| Nickel alloys | ||||||||||||||||

| 600 | DMV 600L | AMS5580 | N06600 | 2.4816 | 0.025 | 16.0 | 76.0 | Fe 8.0 | 8.4 | 0.30 | 180 | 26 | 550 | 80 | ||

| 625 | DMV 625 | AMS5581 | N06625 | 2.4856 | 0.025 | 22.0 | 63.0 | 9.0 | Nb 3.5 Grade 1 | 8.5 | 0.31 | 414 | 60 | 827 | 120 | |

| C263 | DMV C263 | N07263 | 2.4650 | 0.08 | 20.0 | 49.0 | 5.6 | 8.4 | 0.30 | 585 | 85 | 1004 | 145 | |||

| 718 | DMV 718 | AMS5589 | N07718 | 2.4668 | 0.08 | 17.0 | 50.0 | 2.80 | 8.1 | 0.29 | 1100 | 160 | 1375 | 199 | ||

| Alloy 188 | DMV 188 | R30188 | 2.4683 | 0.015 | 22.0 | 22.0 | Co 39.0;W 14.0; Fe < 3.0 | 9.1 | 0.33 | 379 | 55 | 862 | 125 | |||

| Alloy 230 | DMV 230 | N06230 | 2.4733 | 0.1 | 22.0 | 57.0 | 9.0 | 0.32 | 310 | 45 | 758 | 110 | ||||

| Pure Nickel | ||||||||||||||||

| Ni 200 | DMV 200 | ASTM B161 | N02200 | 2.4066 | 0.05 | 99.4 | 8.9 | 0.32 | 103 | 15 | 379 | 55 | ||||

| Ni 201 | DMV 201 | ASTM B161 | N02201 | 2.4068 | 0.05 | 99.4 | 8.9 | 0.32 | 83 | 12 | 345 | 50 | ||||

Quality Approvals

Our global quality management system with its extensive approvals and accreditations from the nuclear, oil & gas and petrochem sectors is complemented with both aerospace quality approvals and accreditations of leading aerospace organisations thru customer audit.