Health & Safety

Zero Accident – our goal, our focus, our culture.

Across our global manufacturing locations the health & safety of everyone on our sites is paramount. The wellbeing of employees, contractors and visitors remains our number one priority.

The zero accident mantra is a mind-set which extends from our leadership team through the entire organisation.

The fundamental steps we follow are:

Engagement: the empowerment, involvement and participation of personnel through routine information, education and training. Embedding the highest ethical standards of behavioural integrity combined with open and honest communication.

Awareness: we continually reinforce ‘awareness’ and encourage behaviours which self-motivate and ensure a continual journey of learning and improvement. We operate in a manufacturing environment where, by nature of the processes we follow hazards shall be identified and avoided. We continually review and assess hazards and related risks and from this we take actions to improve health & safety in the work environment.

Compliance: to embrace, meet & exceed the respective local legislation requirements and the expectations of the Salzgitter Group for health & safety at work.

Targets: we define occupational ‘safety’ targets which are communicated across the global organisation. We measure, review and challenge our progress.

Quality Management

At Mannesmann Stainless Tubes we take pride in meeting and exceeding our customer’s quality expectations

We encourage and seek feedback on our performance and from this how we may learn and continuously improve. In our most recent customer survey we obtained a 100% quality score across our global manufacturing plants.

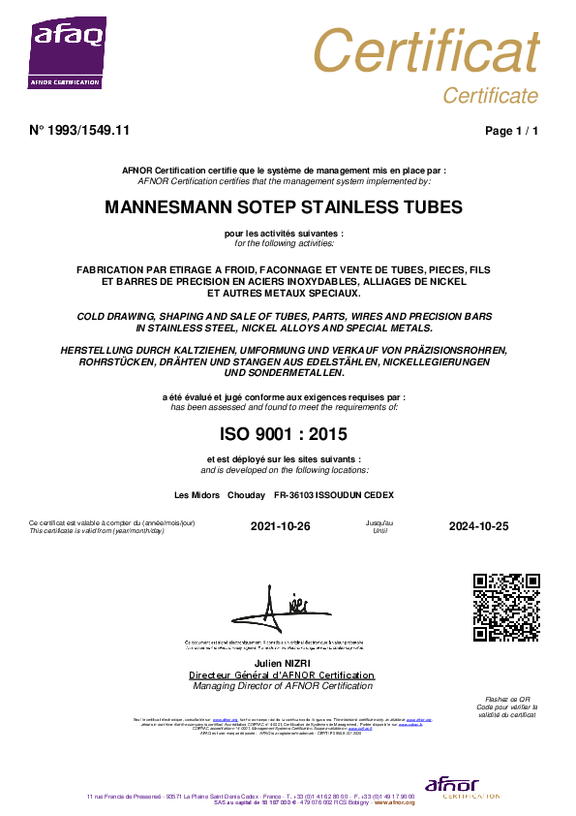

We have quality management systems which are routinely audited and approved by the world’s leading organisations such as: ASME, ISO, TUV, DNV, JIS and Lloyd’s Register.

Our plants hold approvals which include, for example, ISO 9001, ISO 14001 & IS0 45001.

Below you can find PDFs of the certificates. Contact us if you have questions about these or other approvals and certificates.

Other quality management system approvals, accreditations & qualifications - copies available upon request from your local sales contact.

- API 5LC

- API 5CRA

- ASME: QSC NCA3800

- ABS: ABS Rules

- DNV GL: Rules for classification- ships

- DNV GL: Offshore standards

- Lloyd's Register: Requirements of Lloyd's Register

- NNSA (National Nuclear Safety Administration): HAF 604

- Sercons International- Russian Certification Authority in Europe: EAC regulation TR TC 032/2013

- STOOMWEZEN BV: M 0303 Appendix 2

- TuV SUD Industrie Service: KTA 3201.1 section 2.4

- NORSOK Std M650 Rev 04 Qualification.

Sustainability

We are mindful not just of our responsibility for sustainability but how we embed this into our everyday culture, across the global organisation.

We combine best sustainability and environmental behaviours such that working with our customers, employees, partners and supply chain we can shape a sustainable future.

Our routine practices and achievements have focal points on

Increasing our energy efficiencies and reducing our electric energy consumption.

The continuous review and improvement on all manufacturing processes such as to master the use of all hazardous substances which are involved in the production of stainless steel and nickel alloys.

Traceability:

The Mannesmann quality stamp gives the important re-assurance of full traceability. From the origin of our raw materials, their verification and the internal control processes which then follow you can be take peace of mind that quality is one of our core business principles.