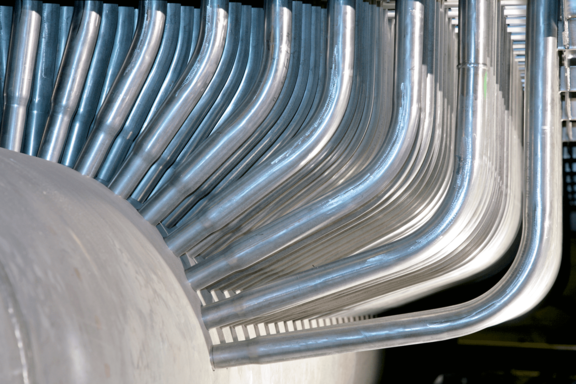

Application: Boiler Tubes

At the heart of our pedigree and experience is the production of boiler tubes, using the latest production technologies to ensure excellence of quality is combined with innovation in materials.

As today's conventional power plants evolve in terms of operating efficiencies and environment controls so the operating environments become ever more challenging.

Advanced ultra supercritical power plants with operating temperatures of 700 ºC (1292 ºF) and pressures > 350 bar demand materials which demonstrate high temperature creep strength, enabling the improved optimisation of wall thickness.

Our boiler tubes size range of cold finished seamless tubes is complemented by our extensive range of heat exchanger and instrumentation sizes.

Product: Boiler Tubes

| OD range | mm | Inch |

| min | 33.0 | 1.3 |

| max | 76.0 | 3.0 |

| WT range | mm | Inch |

| min | 2.0 | 0.08 |

| max | 16.0 | 0.63 |

Equivalent Grades According To National And International Standards

| MST designation | Germany | USA | France | Great Britain | Japan | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| W-Nr | DIN | UNS | ASTM | Designation | NFA | Designation | BS | Designation | JIS | |

| DMV 304H | 1.4948 | 17459 | S30409 | A 376 1) | Z 6 CN 19-10 | 49-214 | 304 S51 | 3059 | 304 HTP | 3459 |

| DMV 304HCu | 1.4907 | Code Case 2328-1 | ||||||||

| DMV 304N | 1.4949 | 17459 | S30451 | A 376 1) | 304 S51 | 3059 | ||||

| DMV 316H | 1.4919 | 17459 | S31609 | A 376 1) | Z 6 CND 17-12B | 49-214 | 316 S52 | 3059 | 316 HTP | 3459 |

| DMV 321H | 1.4941 | 17459 | S32109 | A 376 1) | Z 6 CNT 18-12B | 49-214 | 321 S51 | 3059 | 321 HTP | 3459 |

| DMV 347H | 1.4550 | 17458 | S34700 | A 376 1) | Z 6 CNNb 18-10 | 49-218 | 347 S59 | 3059 | 347 HTP | 3459 |

| DMV 347HFG | 1.4908 | Code Case 2159-2 | ||||||||

| DMV 4910 | 1.4910 | 17459 | S31653 | A 376 1) | Z 6 CN 19-10 | 49-214 | 316 S51 | 3059 | ||

| DMV 310N | 1.4952 | S31042 | A 213 | |||||||

| DMV 800H | 1.4958 | 17459 | N08810 | B 407 | Z 8 NC 32-21 | 35-578 | NA 15 | 3074 | NOF800 H | |

| DMV 800HT | 1.4959 | 17459 | N08811 | B 407 | Z 8 NC 32-21 | 35-578 | NA 15 | 3074 | NOF800 H | |

| DMV AC66 | 1.4877 | S33228 | A 213 | |||||||

| DMV 600H | 2.4816 | 17751 | N06600 | B 167 | Z 8 NC 75 15 | NA 14(H)3074 | 3074 | NOF600H | ||

| DMV 617 / DMV 617 mod. | 2.4663 | N06617 | B 622 | |||||||

1) also ASTM A 213, ASTM A 312, ASME | ||||||||||

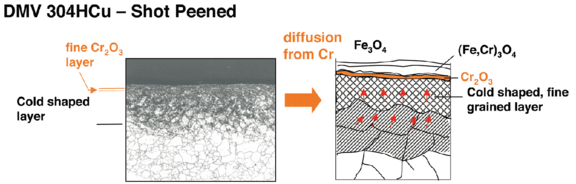

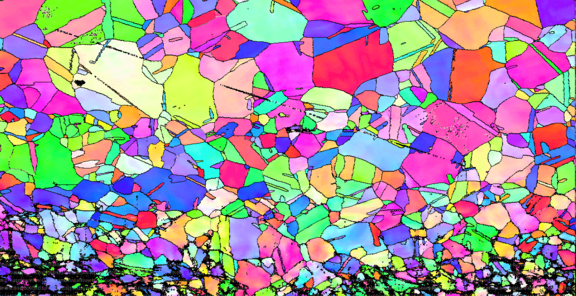

Shot Peening

Shot Peening is a cost-effective technique to refine austenitic superheater and reheater tubes, on grades like DMV 304HCu, DMV 347, DMV 347HFG and DMV 4910.

Treating the inner surface of the tube with particles of its own grade, creates a cold shaped, fine grained layer. While in use inside a power plant at temperatures about 570 °C (1058 °F), a permanent and dense layer of chromium oxide is formed that steadily protects the tube from its inside.

Shot peened tubes can be used in power plants at higher temperatures and offer an increased service life, compared to other superheater or reheater tubes. That makes it an alternative to products in price volatile chrome and nickel alloys.

HRSG Heat Recovery Steam Generator Tubes

Our heat recovery steam generator tubing is at the heart of the process for the continual drive towards improving thermal operating efficiencies of today’s power plants.

With straight lengths up to 30 m (98 ft) long we offer stainless and nickel alloys suitable for environments demanding high thermal fatigue, creep and corrosion fatigue properties.

Creep Properties

| MST designation | Heat treatment condition | Temperature (°C) Creep strength (MPa) after … | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10.000 hours | 100.000 hours | 200.000 hours | |||||||||||||||||

| DMV 304H | solution annealed | 550 250 | 600 132 | 650 87 | 700 55 | 750 (34) | 550 192 | 600 89 | 650 52 | 700 28 | 750 (15) | 550 176 | 600 78 | 650 43 | 700 22 | ||||

| DMV 304HCu | solution annealed | 600 240 | 650 160 | 700 101 | 750 61 | 600 182 | 650 116 | 700 68 | 750 37 | ||||||||||

| DMV 304N | solution annealed | 550 230 | 600 160 | 650 100 | 550 178 | 550 178 | 600 114 | 650 64 | 700 30 | ||||||||||

| DMV 316H | solution annealed | 550 250 | 600 175 | 650 111 | 700 65 | 550 175 | 600 120 | 650 69 | 700 34 | ||||||||||

| DMV 321H | solution annealed | 550 230 | 600 160 | 650 100 | 700 60 | 700 60 | 600 100 | 650 62 | 700 35 | 500 150 | 600 90 | 650 54 | 700 29 | ||||||

| DMV 347H | solution annealed | 600 115 | 650 70 | 700 45 | 750 28 | 800 (17) | 600 65 | 650 39 | 700 22 | 750 13 | 800 (8) | ||||||||

| DMV 347HFG | solution annealed | 600 215 | 650 142 | 700 90 | 750 53 | 600 159 | 650 100 | 700 58 | 750 30 | ||||||||||

| DMV 4910 | solution annealed | 550 290 | 600 205 | 650 135 | 700 84 | 750 52 | 800 33 | 550 220 | 600 141 | 650 83 | 700 52 | 750 34 | 800 20 | 550 (200) | 600 (122) | 650 (73) | 700 (42) | 750 (28) | 800 (17) |

| DMV 310N | solution annealed | 600 284 | 650 171 | 700 108 | 750 64 | 600 184 | 650 114 | 700 66 | 750 39 | ||||||||||

| DMV 800H | solution annealed | 550 225 | 600 140 | 650 97 | 700 69 | 550 160 | 600 95 | 650 63 | 700 44 | 550 (143) | 600 (83) | 650 (55) | 700 (38) | ||||||

| DMV 800HT | solution annealed | 750 57 | 800 41 | 850 28 | 900 18 | 950 12 | 1,000 7.9 | 750 35 | 800 25 | 850 17 | 900 9.9 | 950 6.2 | 1.000 (4.0) | 750 (30) | 800 (21) | 850 (13) | 900 (8.0) | 950 (4.5) | 1.000 (3.2) |

| DMV AC66 | solution annealed | 700 80 | 750 46 | 800 24 | 900 10 | 950 6 | 1,000 (3.5) | 700 52 | 750 27 | 800 16 | 900 5 | 950 3 | 1.000 (1.5) | ||||||

| DMV 617 | solution annealed | 600 260 | 700 123 | 800 65 | 900 30 | 950 18 | 1,000 10 | 600 190 | 700 95 | 800 43 | 900 16 | 950 8.5 | 1.000 (4.5) | ||||||

| DMV 600H | solution annealed | 600 138 | 700 163 | 800 29 | 850 17 | 900 13 | 600 97 | 700 42 | 800 17 | 850 9.5 | 900 7.0 | ||||||||

| DMV 617 mod. | solution annealed | 600 260 | 650 170 | 700 123 | 750 90 | 600 190 | 650 125 | 700 95 | 750 65 | ||||||||||

An example of how to read the table: creep strength of DMV AC66 after 10.000 hours at 750 °C is 46 MPa | |||||||||||||||||||

Typical Chemical Composition1)

| MST designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Others | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DMV 304H | min. max. | 0.04 0.08 | 0.75 | 2.0 | 0.035 | 0.015 | 17.0 19.0 | 10.0 12.0 | ||||

| DMV 304HCu | min. max. | 0.07 0.13 | 0.30 | 1.0 | 0.040 | 0.010 | 17.0 19.0 | 7.5 10.5 | 0.05 0.12 | Nb(Cb): 0.3-0.6; Cu: 2.5-3.5; Al: 0.003-0.030; B: 0.001-0.010 | ||

| DMV 304N | min. max. | 0.04 | 0.75 | 2.0 | 0.035 | 0.015 | 17.0 19.0 | 9.5 11.5 | 0.20 0.50 | 0.10 0.18 | ||

| DMV 316H | min. max. | 0.04 0.08 | 0.75 | 2.0 | 0.035 | 0.015 | 16.0 18.0 | 12.0 14.0 | 2.0 2.5 | |||

| DMV 321H | min. max. | 0.04 0.10 | 0.75 | 2.0 | 0.035 | 0.015 | 17.0 18.5 | 9.5 11.5 | 0.60 | Ti: 5xC - 0.80; B: 0.0015 - 0.0050 | ||

| DMV 347H | min. max. | 0.04 0.08 | 0.75 | 2.0 | 0.035 | 0.015 | 17.0 19.0 | 9.0 12.0 | Nb: 10xC - 1.0 | |||

| DMV 347HFG | min. max. | 0.06 0.10 | 0.75 | 2.0 | 0.040 | 0.030 | 17.0 20.0 | 9.0 13.0 | Nb(Cb) + Ta: 8xC - 1.0 | |||

| DMV 4910 | min. max. | 0.04 | 0.75 | 2.0 | 0.035 | 0.015 | 16.0 18.0 | 12.0 14.0 | 2.0 2.8 | 0.10 0.18 | B: 0.0015 - 0.0050 | |

| DMV 310N | min. max. | 0.04 0.10 | 0.75 | 2.0 | 0.030 | 0.030 | 24.0 26.0 | 17.0 23.0 | 0.15 0.35 | Nb: 0.20 - 0.60 | ||

| DMV 800H | min. max. | 0.05 0.10 | 0.70 | 1.5 | 0.015 | 0.010 | 19.0 22.0 | 30.0 34.0 | Al: 0.25 - 0.65; Ti: 0.25 - 0.65; Co: max. 0.5 | |||

| DMV 800HT | min. max. | 0.06 0.10 | 0.70 | 1.5 | 0.015 | 0.010 | 19.0 22.0 | 30.0 34.0 | Al: 0.25 - 0.65; Ti: 0.25 - 0.65; Co: max. 0.5 | |||

| DMV AC66 | min. max. | 0.04 0.08 | 0.30 | 1.0 | 0.015 | 0.010 | 26.0 28.0 | 31.0 33.0 | Nb: 0.6 - 1.0; Ce: 0.05 - 0.10; Al: max. 0.025 | |||

| DMV 600H | min. max. | 0.06 0.08 | 0.50 | 1.0 | 0.015 | 0.015 | 14.0 17.0 | 72.0 | Fe: 6.0 - 10.0 | |||

| DMV 617 | min. max. | 0.05 0.10 | 0.70 | 0.7 | 0.012 | 0.008 | 20.0 23.0 | Remainder | 8.0 10.0 | Co: 10.0 - 13.0; Ti: 0.2 - 0.5; Al: 0.6 - 1.5 | ||

1) All figures in weight percentage. In case of order, the limits of the order specification will apply. | ||||||||||||

Mechanical Properties At Elevated Temperatures

| MST designation | Heat treatment condition | Rp0.2 (MPa) min. at (°C) | Rp1.0 (MPa) min. at (°C) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | ||||

| DMV 304H | solution annealed | 157 | 127 | 108 | 98 | 88 | 83 | 78 | 191 | 157 | 137 | 127 | 118 | 113 | 108 | ||||

| DMV 304HCu | solution annealed | 205 | 180 | 170 | 160 | 150 | 145 | 140 | 230 | 205 | 195 | 185 | 175 | 170 | 165 | ||||

| DMV 304N | solution annealed | 185 | 150 | 130 | 120 | 110 | 105 | 100 | 220 | 175 | 150 | 140 | 130 | 125 | 120 | ||||

| DMV 316H | solution annealed | 177 | 147 | 127 | 118 | 108 | 103 | 98 | 211 | 177 | 157 | 147 | 137 | 132 | 128 | ||||

| DMV 321H | solution annealed | 162 | 142 | 132 | 123 | 113 | 108 | 103 | 201 | 181 | 172 | 162 | 152 | 147 | 142 | ||||

| DMV 347H | solution annealed | 177 | 157 | 136 | 125 | 119 | 118 | 211 | 186 | 167 | 156 | 149 | 147 | ||||||

| DMV 347HFG | solution annealed | 182 | 163 | 152 | 143 | 136 | 134 | 131 | 126 | 217 | 198 | 187 | 173 | 161 | 159 | 156 | 151 | ||

| DMV 4910 | solution annealed | 205 | 170 | 148 | 134 | 127 | 124 | 121 | 240 | 200 | 178 | 164 | 157 | 154 | 151 | ||||

| DMV 310N | solution annealed | 240 | 205 | 190 | 180 | 170 | 165 | 160 | 160 | 265 | 230 | 210 | 200 | 190 | 185 | 180 | 180 | ||

| DMV 800H | solution annealed | 140 | 115 | 95 | 85 | 80 | 75 | 75 | 160 | 135 | 115 | 105 | 100 | 95 | 95 | ||||

| DMV 800HT | solution annealed | 140 | 115 | 95 | 85 | 80 | 75 | 75 | 160 | 135 | 115 | 105 | 100 | 95 | 95 | ||||

| DMV AC66 | solution annealed | 160 | 140 | 120 | 105 | 95 | 90 | 90 | 190 | 170 | 145 | 130 | 115 | 110 | 110 | ||||

| DMV 600H | solution annealed | 170 | 160 | 150 | 150 | ||||||||||||||

| DMV 617 / DMV 617 mod. | solution annealed | 270 | 230 | 220 | 210 | 200 | 195 | 190 | 300 | 260 | 250 | 240 | 225 | 220 | 210 | ||||

| |||||||||||||||||||

Physical Properties

| MST designation | Density (g/cm3) | Modulus of plastic elasticity GPa | Coefficient of thermal mean linear expansion (10-6/K) between 20°C and (°C) | Thermal conductivity W/mK at | Specific heat J/kgK at | Specific electrical resistivity 10 -6 Ωm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 100 | 200 | 400 | 700 | 1.000 | 100 | 200 | 400 | 700 | 1.000 | 20°C | 20°C | at 20° | ||

| DMV 304H | 7.80 | 198 | 192 | 183 | 167 | 142 | 16.3 | 16.9 | 17.8 | 18.7 | 17 | 450 | 0.70 | ||

| DMV 304HCu | 7.80 | 189 | 182 | 174 | 156 | 134 | 16.4 | 17.1 | 17.8 | 18.6 | 15 | ||||

| DMV 304N | 7.81 | 198 | 192 | 183 | 167 | 142 | 16.3 | 16.9 | 17.8 | 18.7 | 17 | 450 | 0.70 | ||

| DMV 316H | 7.88 | 198 | 192 | 183 | 167 | 142 | 16.3 | 16.9 | 17.8 | 18.7 | 16 | 450 | 0.77 | ||

| DMV 321H | 7.80 | 198 | 192 | 183 | 167 | 142 | 16.3 | 16.9 | 17.8 | 18.7 | 17 | 450 | 0.70 | ||

| DMV 347H | 7.83 | 200 | 16.0 | 17.0 | 18.0 | 15 | 500 | 0.73 | |||||||

| DMV 347HFG | 7.83 | 200 | 190 | 185 | 170 | 145 | 16.3 | 16.9 | 17.8 | 18.7 | 14 | ||||

| DMV 4910 | 7.91 | 198 | 192 | 183 | 167 | 142 | 16.3 | 16.9 | 17.8 | 18.7 | 16 | 450 | 0.77 | ||

| DMV 310N | 7.83 | 193 | 191 | 184 | 167 | 144 | 13.4 | 15.6 | 17.0 | 17.9 | 12 | ||||

| DMV 800H | 7.97 | 197 | 191 | 184 | 170 | 148 | 127 | 15.4 | 16.0 | 16.8 | 17.9 | 19.0 | 12 | 460 | 0.99 |

| DMV 800HT | 7.98 | 197 | 191 | 184 | 170 | 148 | 127 | 15.4 | 16.0 | 16.8 | 17.9 | 19.0 | 12 | 460 | 0.99 |

| DMV AC66 | 7.98 | 191 | 195 | 179 | 166 | 144 | 119 | 14.0 | 16.0 | 19.0 | 23.0 | 28.0 | 12 | 445 | 0.96 |

| DMV 600H | 8.47 | 214 | 214 | 209 | 194 | 172 | 143 | 13.7 | 14.1 | 14.8 | 15.8 | 16.9 | 15 | 455 | 1.03 |

| DMV 617 / DMV 617 mod. | 8.57 | 215 | 215 | 211 | 192 | 169 | 143 | 12.4 | 15.1 | 16.9 | 10 | 420 | 1.22 | ||

| |||||||||||||||