Process Fundamentals

Our production techniques are adapted to the high requirements our customers place on our products.

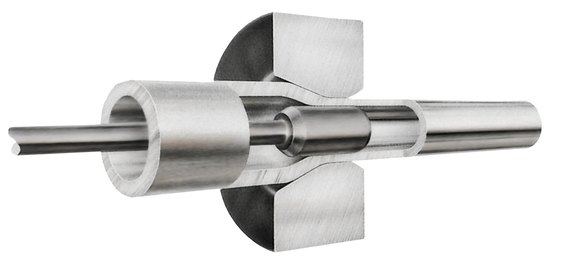

Hot Extrusion

is a production process for manufacturing hot finished tubes, pipes, re-draw hollows and hollow bars in stainless steels and nickel-based alloys. Our range of dimensions includes

- outside diameters from 42 up to 300 mm (1.65 up to 11.81 inches)

- wall thicknesses from 2.7 up to 50 mm (0.11 up to 1.97 inches)

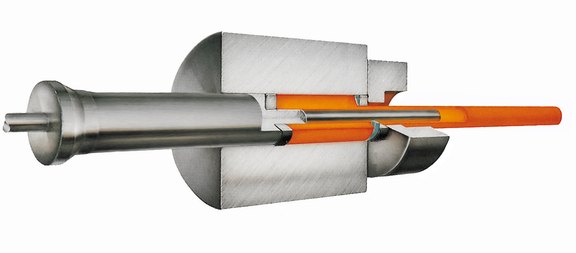

Cold Pilgering

is the preferred production process for seamless, cold- finished, high alloyed stainless steel and nickel-based alloy tubes and pipes. This technique provides a highly efficient, fast production rate, close tolerances and cost-effective, competitive products.

Our production range covers

- outside diameters from 6 mm to 244.5 mm ( 0.24” to 9.62”)

- wall thickness from 0.5 mm to 30 mm ( 0.02” to 1.18”)

Cold Drawing

is the ideal process for achieving very close tolerance ranges, especially for outside diameters. Additionally, the cold drawing process is the perfect choice when a low forming ratio is required.

- outside diameters from 1.6 mm to 51 mm ( 0.063” to 2.0”)

- wall thicknesses from 0.05 mm to 6 mm ( 0.002” to 0.24”)